RJ45 Patch cord manufacturing process and equipment

1.Prepare raw materials.(Connectorand cable )

2.Process cable———wire feeder machine&automatic wire cutting and stripping machine

![]()

![]()

![]()

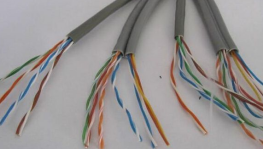

3.Separate and straighten the twisted pair of cable——–BY Network cable separate and straighten machine

![]()

4.Manual combined cable with RJ45 connector.

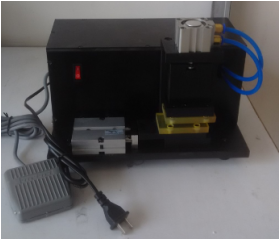

5.Crimping RJ45 connector with cable –By AM-RJ45 crimping machine

![]()

![]()

6.Patch cord cable connector Injection molding ———–injection molding machine and some matching machines for dealing raw materials and molding

Injection molding machine and matching mold

![]()

Deal with plastic raw materials

![]()

Plastic Material Drying Machine Plastic Material Mixing Machine Plastic Material Crushing Machine

![]()

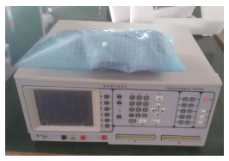

7.Cable Performance Testing———–By Cable performance Testing machine

This machine can test all kinds of electric cable,like usb cable,network cable,video cable,flat cable etc.

![]()

8.Winding and Packing the USB cable————-Semi-automatic cable winding and bundling machine

![]()

9. Packing the cable into bag

![]()

(Above machines are necessary machines for manufacturing patch cord cable)